| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : NANYA

Model Number : ER3000-B~ER6000-B

Certification : CE

Place of Origin : Guangdong, China(Mainland)

MOQ : Negotiable

Price : Negotiation

Payment Terms : L/C, T/T,Cash, Western Union

Supply Ability : 100 sets/ years

Delivery Time : Normally 100-120 days

Packaging Details : Strong and Suitable for Marine Shipment

Product Name : Egg Tray Machine

Process Type : Pulp Molding Equipment

Output : 3000~6000pcs/hour

Material : Recycle paper pulp

Application : Egg tray/egg box/fruit tray/ kidney tray...

Forming Type : Rotary Forming and Transfer

Automation : Fully Automatic

Speed : 2.2-3 seconds/ drop

Control By : PLC + Touchscreen

Max. Product Height : 70 mm

Fully Automatic 30 Holes Egg Box Tray Rotary Pulp Molding Equipment

Specifications:

| Model | Capacity | Forming Machine | Drying System | Workshop Space | Operator Required |

| ER3000-B | 3000pcs/hour | Rotary type with 8 plates. Each for 3pcs/time | 20x2.2x4m 6-Layers | 400m2 | 4~5persons |

| ER4000-B | 4000pcs/hour | Rotary type with 8 plates. Each for 4pcs/time | 20x2.6x4m 6-Layers | 500m2 | 4~5persons |

| ER5000-B | 5000pcs/hour | Rotary type with 8 plates. Each for 5pcs/time | 20x3.0x4m 6-Layers | 600m2 | 4~5persons |

| ER6000-B | 6000pcs/hour | Rotary type with 8 plates. Each for 6pcs/time | 20x3.4x4m 6-Layers | 700m2 | 5~6persons |

| Notess: 1. The Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 65g~70g). 2. Workshop size is for reference only and could be adjusted according to actual size of client’s plant . | |||||

Production Consumption:

| Model | Electricity Consumption | Material Consumption | Water Consumption | Natural gas | LPG | Diesel |

| (Choose one one fuel from three fuel type) | ||||||

| ER3000-B | ~115kw (170kw installed) | 180~210kg/h | 600~800kg/h | 55~65m3/h | 19~22m3/h | 45~55kg/h |

| ER4000-B | ~150kw (240kw installed) | 250~280kg/h | 800~1000kg/h | 70~80m3/h | 25~29m3/h | 62~70kg/h |

| ER5000-B | ~190kw (290kw installed) | 320~350kg/h | 1000~1200kg/h | 85~95m3/h | 31~35m3/h | 79~87kg/h |

| ER6000-B | ~210kw (350kw installed) | 360~400kg/h | 1200~1400kg/h | 100~110m3/h | 36~40m3/h | 92~100kg/h |

Descriptions:

Product Name: Automatic Egg Tray Production Line

Processing Type: Pulp Molding Machine

Place of Origin: Guangdong, China

Approval: CE Certification

Warranty: Life-long service, sustainable supply and upgrade machine and parts. 1 year warranty( three-year warranty for main machine)

Capacity: 3000~6000pcs/hr (30-egg tray)

Mainly applied for egg tray, egg carton, fruit tray, cup carrier, vegetable tray, kidney tray seeding cups and etc.

Raw material: Any kind of waste paper like waste carton, old newspaper, books, A4 paper etc.

Automation: Fully-automatic control

How the Production Line Works:

1. Pulping System: Turn waste paper, such waste carton, used newspaper, into pulp of certain consistency. Main equipment: hydrapulper, pulp tanks, water tank, pulp pump, water pump, agitator, etc.

2. Forming Syatem: When adjusting the pulp consistency, the pulp will go to the forming machine. With the help of vacuum and compressed air, the products will be formed on the moulds.

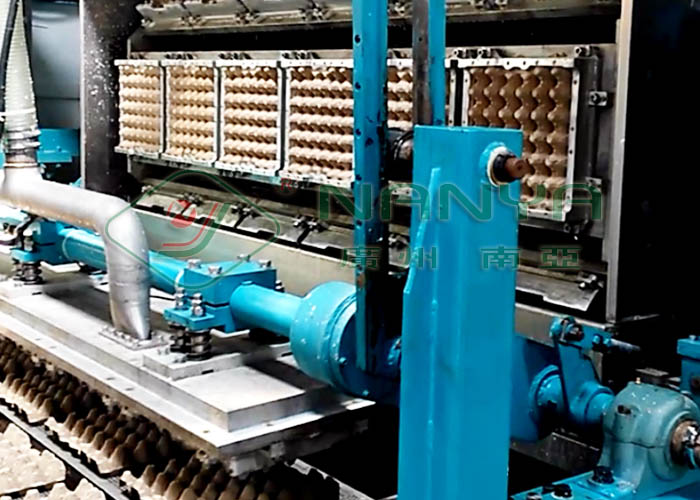

3. Drying System: After forming, the tranfer moulds will move forward and put on the dryer automatically. you can choose Natural gas / LPG / Diesel / Heavy oil / Steam / Wood / Coal to heat up the wet products.

4. Vacuum System: Supply vacuum for forming machine.

5. Air Compressor System: Supply compressed air for forming machine.

6. Stacking & Packing System: Cutting the extra edges of products, to get more compact and neat edge.

YOUTUBE Links:

4000pcs/h with 6 layers dryer: https://www.youtube.com/watch?v=85eeIP8xCEY&t=3s

6000pcs/h with 6 layers dryer: https://www.youtube.com/watch?v=YIeLPQnwO4M

3000pcs/h with single layer dryer: https://www.youtube.com/watch?v=CX9NgjBZ0Nk

4000pcs/h with single layer dryer: https://www.youtube.com/watch?v=JCu3xNpnCsM

6000pcs/h with single layer dryer: https://www.youtube.com/watch?v=9XpyL-ggwi4

For more videos, you can search "Guangzhou Nanya Pulp Molding Equipment Company" on YOUTUBE and subscribe us.

Applications:

1. Egg trays / 6 cells egg box / 10 cells egg box / 12 cells egg box;

2. Fruit trays / cup trays / seeding cups / agricultral cups / shoe tree;

3. Innner industrial packages, like for TV, fan, battery, air conditioner and other electrical items

4. Disposable Medical Care Products, like Bedpan, sick pad, urinal pan…

What We Provide:

1. Pulp Molding Machine Manufacturing, including egg tray/egg box/ fruit tray machines, tableware thermoforming machines, machines for general quality industrial packages and high quality industrial packages.

2. Mould, Tool and Die Set Manufacturing. We have our mould CNC center, we have professional team for designing and making moulds.

3. Project Management/whole production line. We will make quotation and analysis based on customer’s investment and capacity and provide the complete production line.

4. Training and Transfer of know-how. We will send 2 engineers to customer's plant for installation guidance and debug; Training includes the structure explanation of the equipment, production technology, maintenance and common troubleshooting and practical exercises.

Business Terms:

| NO. | ITEM | DESCRIPTION |

| 1 | Delivery Port | Guangzhou or Shenzhen, China. |

| 2 | Delivery Time | Normally 100~120 days |

| 3 | Packages | Strong and Suitable for Marine Shipment |

| 4 | Installation | Appoint 2 engineers to instruct buyer for installation, test-run and training. |

| 5 | Warranty | Life-long service, one year warranty( three year warranty for main machines) |

|

|

PLC 70mm 30 Holes Egg Tray Pulp Molding Equipment Images |